Model Rocket Payload System

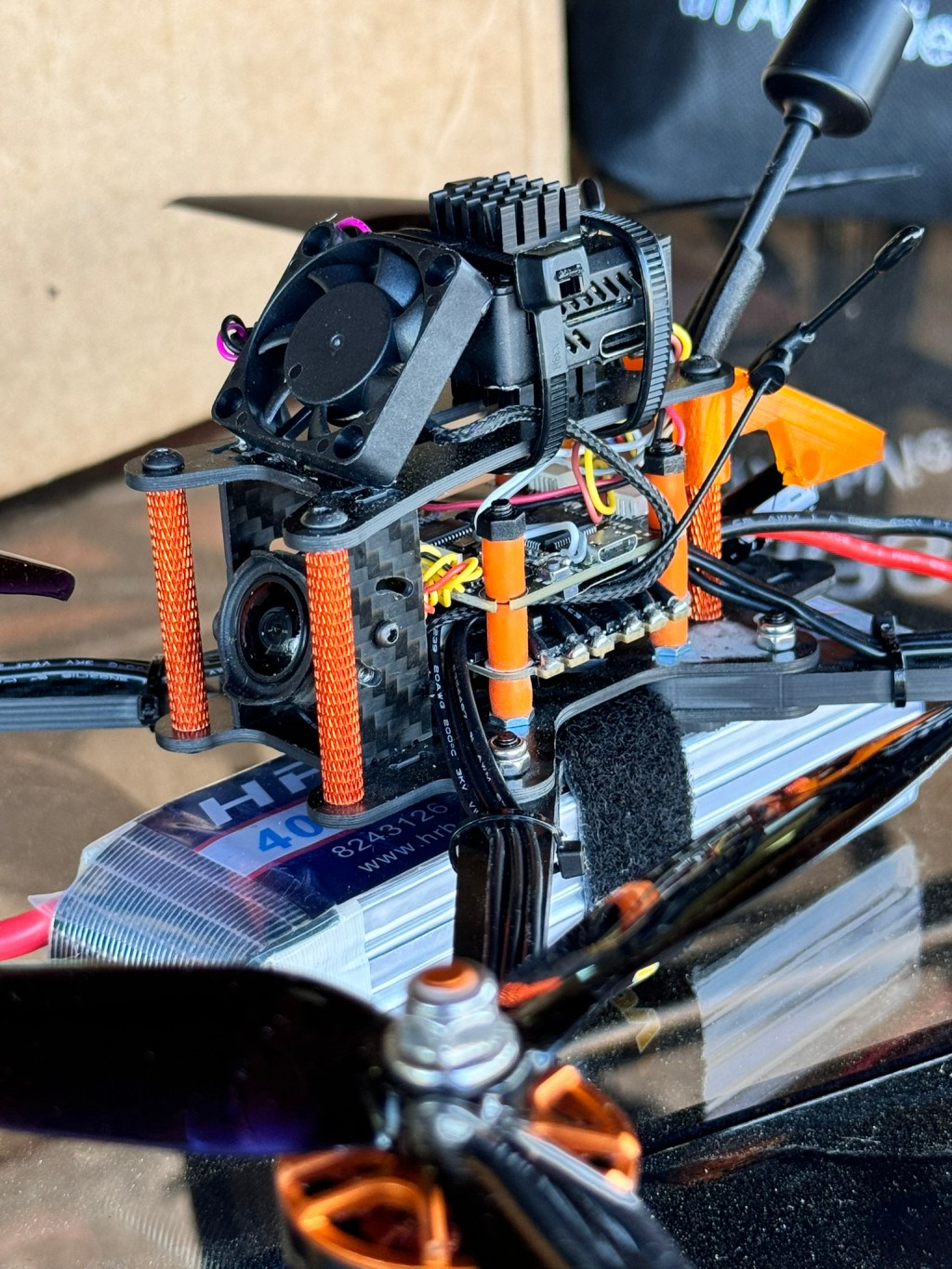

This project is a passive FPV payload avionics stack designed for use in small model rockets. The objective was to create a compact, self-contained video transmission module that fits cleanly inside a standard cylindrical payload section while maintaining mechanical robustness, thermal stability, and reliable RF performance.

The housing was designed and 3D printed from scratch, with internal geometry tailored specifically around the electronics used. The design prioritizes axial alignment, controlled mass distribution, and serviceability rather than simply packing components into a tube.

System Overview

The payload stack consists of:

- A forward-facing FPV camera mounted at the top of the stack for an unobstructed field of view

- A video transmitter mounted centrally within the structure

- An onboard battery isolated to the lower section of the module

- A rear-routed antenna connection for RF transmission

- Integrated wiring paths and strain relief to reduce connector fatigue under vibration

The system provides live video transmission only. It has no control authority, no interaction with propulsion or recovery systems, and no effect on vehicle guidance beyond the passive mass it introduces.

Mechanical Design

The cylindrical housing was modeled to match common model rocket payload diameters and includes precision cutouts for:

- Camera visibility

- Heat dissipation

- Cable routing and access

Internal mounting features constrain each component in all axes, preventing relative motion during boost and coast phases. The structure maintains concentric alignment with the rocket body to avoid unintended center-of-gravity offsets caused by asymmetric mounting.

Thermal Considerations

During bench testing, the video transmitter showed thermal sensitivity during extended operation. To improve stability, a dedicated heatsink was added directly to the VTX to reduce thermal buildup and prevent output degradation during sustained transmission.

Ventilation openings were incorporated into the housing to allow passive airflow while maintaining structural integrity.

Electrical Architecture

The electronics are intentionally simple and isolated:

- Battery to video transmitter

- Video transmitter to camera

- Video transmitter to antenna

There are no microcontrollers, flight sensors, or actuation interfaces. This minimizes failure modes and ensures the payload remains strictly observational.

Design Intent

This project explores the space between consumer model rocketry and real aerospace instrumentation. It is not a toy and not a flight-critical system. It is an experimental imaging payload intended to demonstrate how avionics packaging principles scale down into constrained hobby platforms.

All design decisions, including component placement and thermal mitigation, were driven by first-principles engineering rather than off-the-shelf assumptions.

Leave a comment